On building projects with strict timelines and high standards for quality, you must find a means to do more without overloading staff. Additionally, you need light-weight, agile tools that can pass gates, cover uneven terrain, and turn without destroying nearby buildings or machinery.

Often the ideal answer are small excavators. They provide you the ability to minimize damage and offer great flexibility, thereby enabling you to get tasks completed quickly. We will go over how to run a small excavator in the tutorial below and go over how these machines could help a range of applications.

Table of Contents

ToggleDescribes a Mini Excavator.

Many times utilized in building projects, a tiny excavator is a flexible tool. Though smaller and lighter than a conventional excavator, it can easily carry out many necessary tasks. Usually, mini excavators consist of many basic parts:

Users of the small excavator sit in the cab to operate it.

The mini excavator runs on an engine, which lets the operator control the boom and drive with hydraulic tracks.

The tiny excavator’s home houses the hydraulic cylinders, engine, and cab underline. Rising on a hinge above the undercarriage, it can turn a complete 360 degrees.

Undercarriage: The undercarriage of the small excavator coupled to the home is its bottom. It supports the weight of the machine and retains the gear, engine, and track roller, allowing the mini excavator to operate.

The long hinged, hydraulically driven arm is the stick. It may link to accessories like blades, grapples, thumb tools, and trenching buckets. The stick reaches the boom.

A mini excavator’s blade hooks to its undercarriage. It helps with grading and may be positioned front or rear of the small excavator to provide stability during excavation.

Mini excavators vary in weight and size, so you can quickly choose the equipment best for the requirements of your project. Should the purchase price fall short of your means, you may also hire a small excavator. Renting makes around 40% to 50% of the market for mini excavators, so you will be able to discover the necessary alternatives in leased equipment.

Mini Excavators vs. Standard Excavators

What sets micro excavators apart from conventional ones? Let’s review a few ways they vary:

- Mini excavators, as their name implies, are smaller and lighter than conventional excavators. Mini excavators now find a market in equipment weighing less than 10 tons.

- Mini excavators can handle a range of accessories that increase their value.

- Mini excavators often have less environmental effect due to their lesser weight. Mini excavators destroy less soil and plants and leave less, smaller track markings.

- Site suitability: On more confined or congested locations, smaller, micro excavators might be handy. They won’t impede other tools and are simpler to tuck into corners.

- Mini excavators are often simpler to operate, particularly near other objects and vehicles. Additionally easy for Mini excavators to negotiate are packed lots.

- Mini excavators are light, hence, they are simple to load onto trailers and move to and from the work site. A small excavator would be light enough where a conventional excavator could be too hefty for a trailer or utility vehicle to handle.

How to Use a Mini Excavator

Following these guidelines will help you to start utilizing your mini excavator:

- Lower the blade till it tilts the machine somewhat using the control lever.

- Use the throttle for power; if you are new to running a mini excavator, think about using half power for a period until you grow more at ease running the machine.

- Push the main stick to stretch outward and begin digging from there with the bucket. When the stick is about half stretched, use the bucket

- control to turn the bucket at an angle. Lower the boom until the earth meets the bucket’s teeth. As necessary, grace your angle using the joysticks.

- Pull on the stick to have the bucket dig into the ground. Pull the main boom lever then to keep your grade. Should you have a swing boom or variable-angle boom, you may rotate the boom and empty the soil. Alternatively, crank the little excavator and move the soil to the designated dumping site.

The light frames and large variety of attachments of mini excavators make them flexible enough for usage on many various task locations. Mini excavators have many applications listed below:

1. Hole digging

Mini excavators’ special ability to go into difficult-to-reach areas and range of attachment choices help them to be very good for digging. Old-fashioned shoveling is labor-intensive and tiresome; this kind of digging might greatly increase the completion duration of a project. Digging with a little excavator is quick and effective, however.

2. Landscape Design

Mini excavators provide less time-consuming and faster landscaping completion. Using a tiny excavator can help you dig for irrigation ditches or for planting plants and bushes instead of hand shoveling ground. Additionally able to navigate the land without leaving significant track traces or hurting the soil or plants is a lightweight compact excavator.

3. Destroying Building Materials

For destruction as well, mini excavators are handy. Although you wouldn’t likely employ a little excavator to destroy a full-sized building, many building projects call for the destruction of smaller buildings such sheds and other outbuildings. Because of their tiny size, which allows them to negotiate gates and confined areas on the work site, mini excavators are much more efficient and safer than hand-powered equipment for breaking down small buildings.

4. Erecting Outside Structures

When a project calls for building facilities like hot tubs and pools, you want a quick, efficient approach to dig all that soil. Little excavators may be useful. Although shoveling would be a labor-intensive, time-consuming task, a compact excavator will quickly do the work. And it won’t get caught attempting to reach the dig site or rip up the surrounding ground.

Mini Excavator Operation Advice

Knowing the finest ways to tackle tasks with your mini excavator is essential, as it will enable your machine to function as effectively as it could. Here are some pointers for

Mini Excavator Operating Tips

1. Study the Instruction Manual.

Often, the operator’s handbook has insightful advice on using a tiny excavator. It guides you on the usage of every control, where fire extinguishers and warning labels are found, and on the circumstances under which you should and should not use the machine. Often times, a good reading is useful. Nevertheless, even if you do not read every word, be sure to review the handbook to ensure you grasp the fundamental principles of the functioning of the small excavator.

2. Check the machine before use.

Like any vehicle or piece of equipment you run, you should develop the practice of routinely checking over your small excavator. Look for fluid leaks or loose hoses that can endanger your equipment or compromise its operation. Check the coolant, lube, and oil levels; furthermore, look for damage in the tracks.

3. Try the Mini Excavator.

Testing your small excavator and learning how it operates will help you be ready for initial use. Various manufacturers and models have varied layouts, hence, your newest mini excavator could not be exactly like the previous one you had. The machine may be tested in an open, big, level space. Try running all the controls and honing your boisterering and cab rotation. Learning how the mini excavator reacts to controls allows you to increase safety, lower overcorrection, and make your job more exact.

4. Run Practice Driving on Tracks

Most small excavators run on rubber tracks, which manage very differently than wheeled axles. To better turn, the right and left tracks may even move apart. If you have never driven a mini excavator, practice to gain a solid feel for how the terrain and controls affect the tracks.

5. Verify Right Balance

Particularly with smaller machines, you might find yourself tilting if you improperly balance the weight of your mini excavator. Extending or retracting the stick helps you to balance your little excavator.

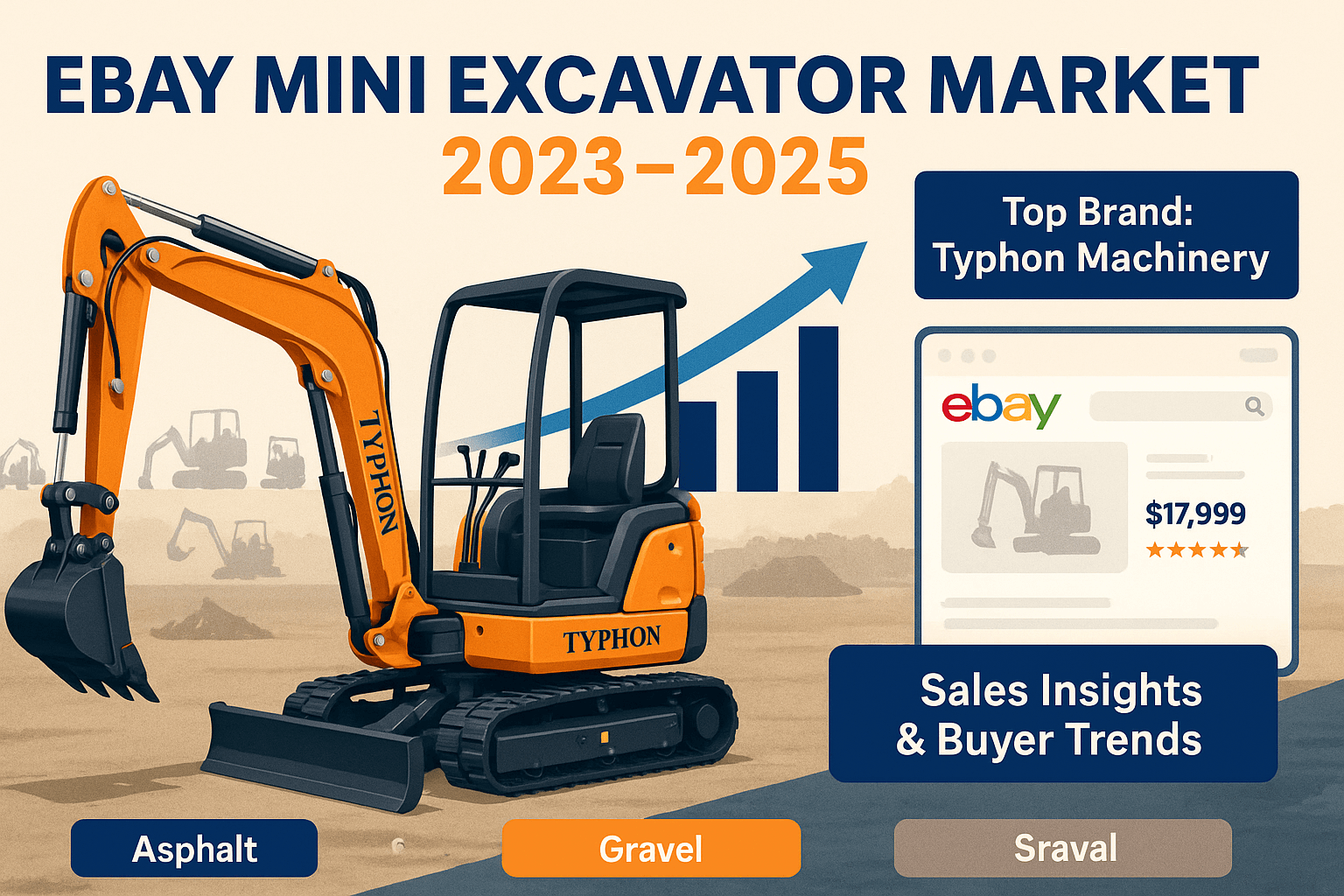

Call TYPHON Machinery for All Your Mini Excavator Requirements.

You should start using some of the little excavator advice you have read now. Work with TYPHON Machinery to explore the advantages of a small excavator for your next project.

TYPHON Machinery has been available to support you in succeeding construction, excavation, and landscaping projects since 2010. Our large selection of little excavators spans a variety of sizes and powers. We also have the most complete components in the business and back our equipment with factory-trained employees ready to provide on-site service.

Contact us or give us a call today at +1 424 653 6764