Table of Contents

ToggleEnsuring Safety with Mini Excavators on Construction Sites

Mini Excavator safety is not just a protocol; it’s a necessity that safeguards lives on construction sites. Construction workers, safety officers, and site supervisors must be vigilant about safety measures when operating these powerful machines. This blog post aims to equip you with essential excavator safety tips, focusing on the safe operation of mini excavators, which are increasingly popular in the industry. Expect to gain insights into common hazards, operational best practices, and the collective responsibility of maintaining a secure work environment.

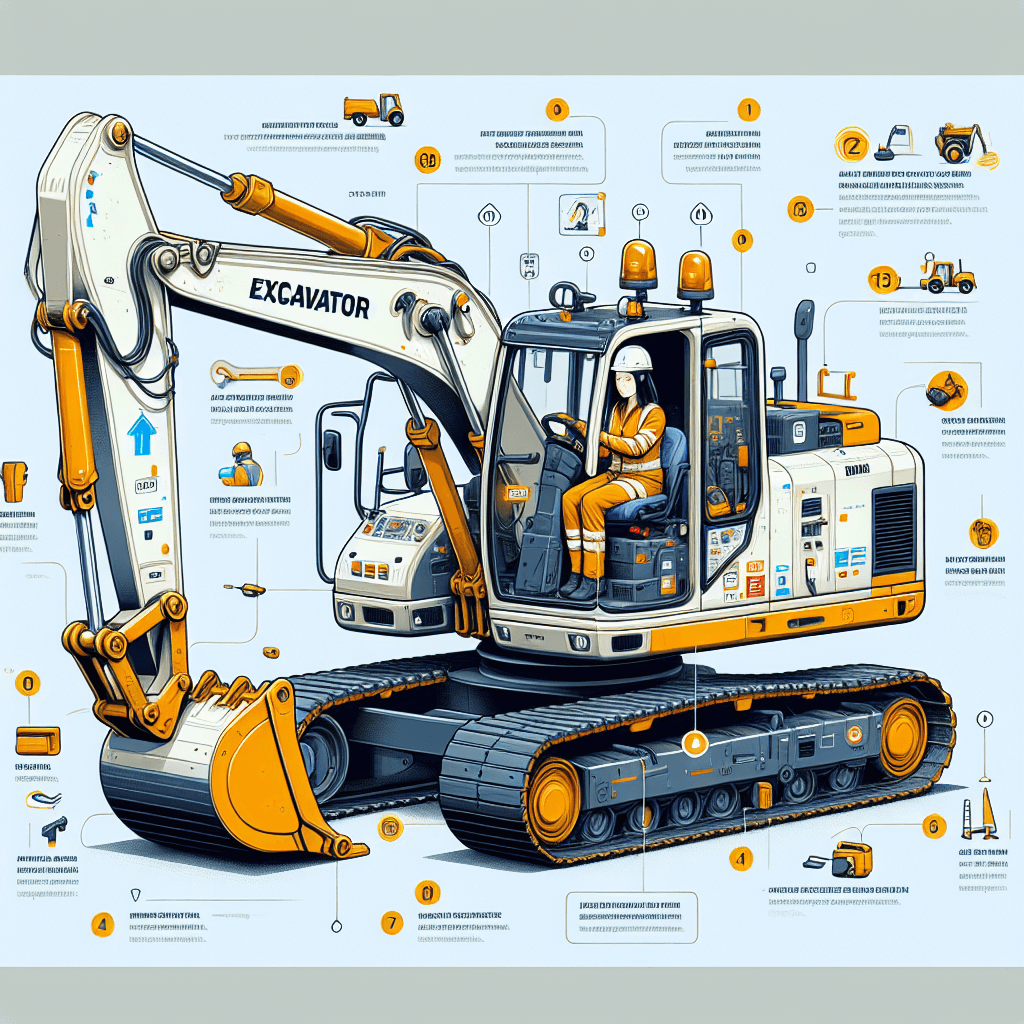

Understanding Excavator Operations on Construction Sites

Excavators are indispensable machines in the construction industry, primarily used for digging, lifting, and removing earth. Mini excavators, in particular, provide versatility and maneuverability in confined spaces. They are often involved in laying foundations, trenching, and material handling. Understanding the typical operations of excavators helps in recognizing their potential risks and implementing necessary safety measures.

These machines are equipped with a boom, dipper, and bucket, and are capable of rotating 360 degrees, making them highly efficient. However, this mobility also introduces specific safety challenges that operators and site personnel need to be aware of. Familiarizing oneself with the operations and limitations of mini excavators is the first step towards ensuring a safe construction site.

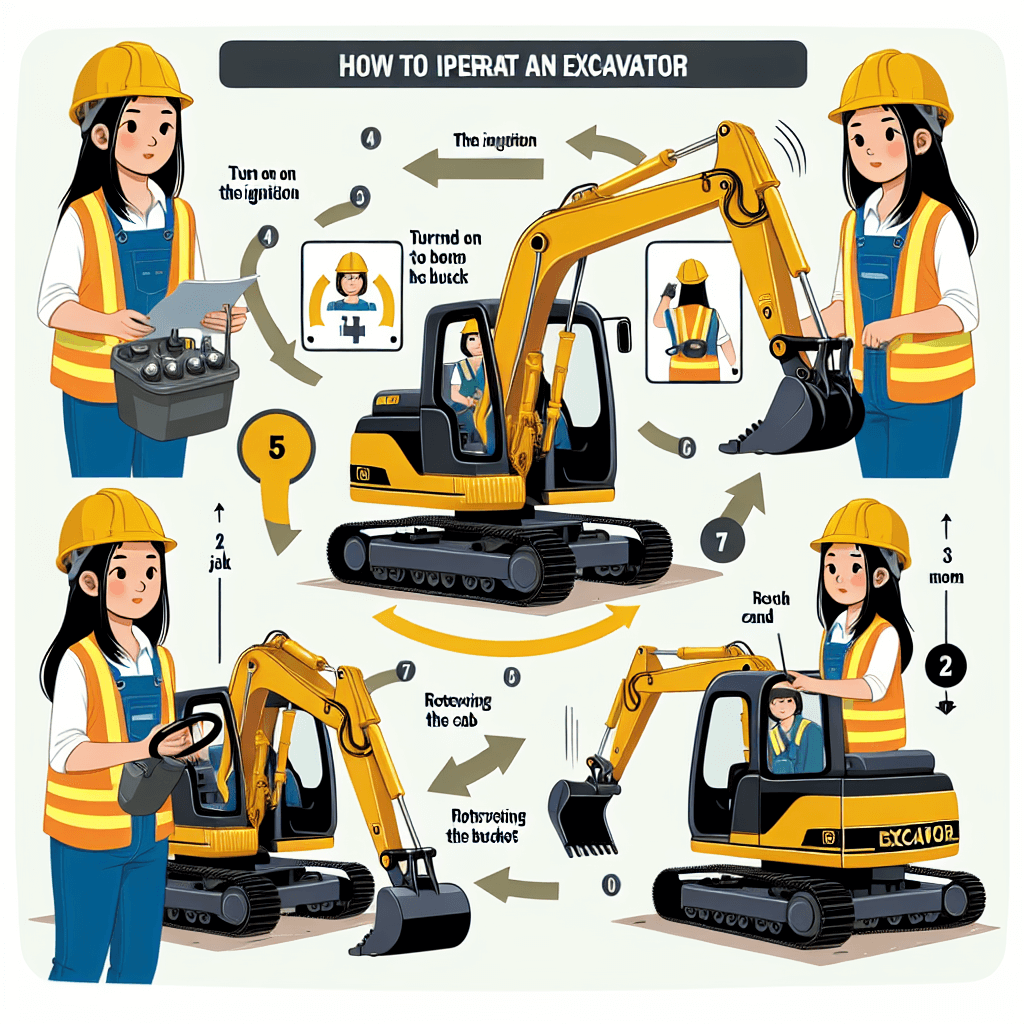

How to Operate an Excavator

Operating an excavator requires skill, knowledge, and strict adherence to safety protocols. Here is a comprehensive guide for excavator operators on how to operate these powerful machines effectively:

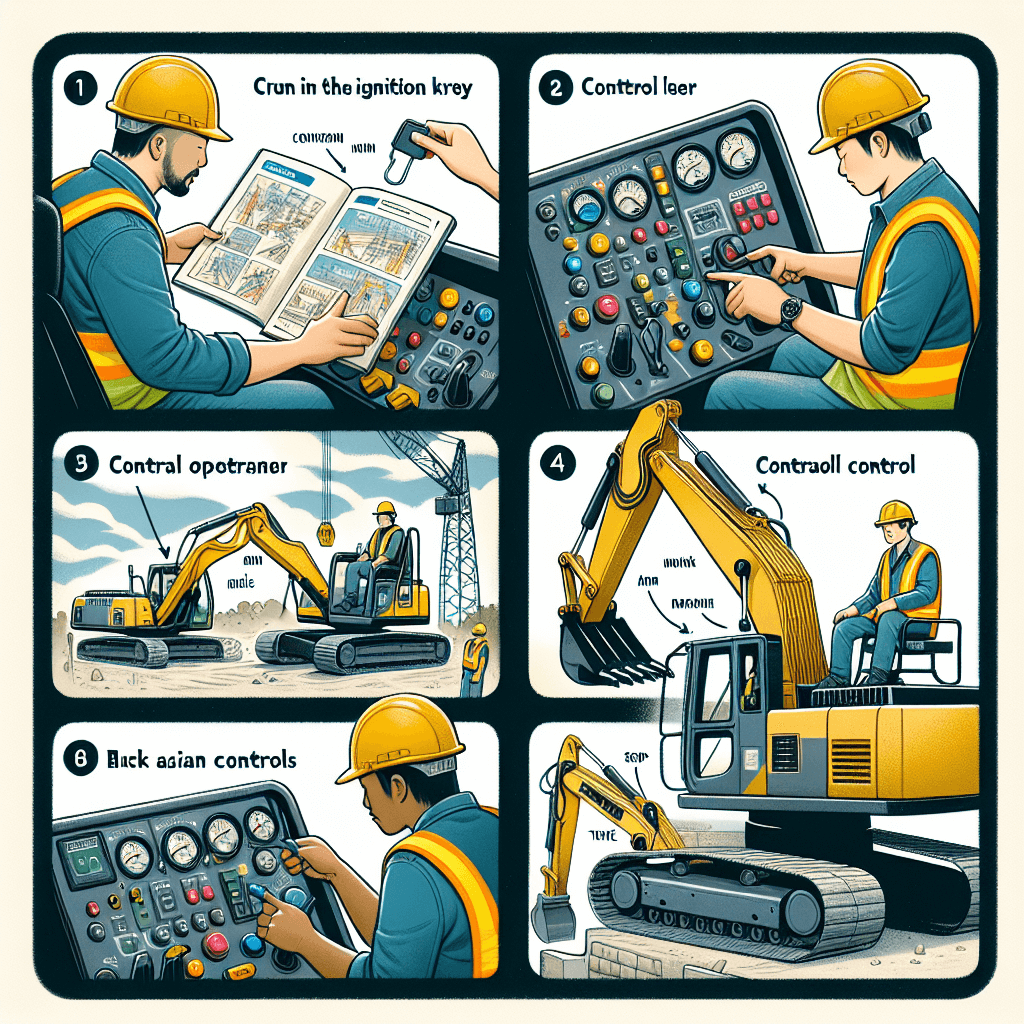

Familiarization of Controls

Before you commence operations, it is crucial to become thoroughly acquainted with the excavator’s controls. These typically include levers that manage the hydraulic arm and bucket, foot pedals for controlling the tracks (crawlers), and various switches for auxiliary functions. Always refer to the operator’s manual relevant to your specific excavator model to understand the control layout and their respective functions.

Perform Pre-Operational Checks

A meticulous pre-operational check is paramount before starting the excavator. Inspect the machine for visible damage, leaks, or loose components. Any identified issues must be reported immediately, and the machine should not be utilized until it receives a thorough inspection and validation to proceed.

Cabin Layout and Visibility

To ensure optimal operation, familiarize yourself with the cabin’s layout, paying close attention to the location of essential controls and instruments. Ensure that all windows are clean, providing unobstructed visibility of the worksite and surrounding areas.

Starting the Excavator

Start the excavator’s engine in accordance with the manufacturer’s instructions. Allow the machine to warm up before engaging in operations, monitoring the engine’s temperature and pressure gauges to confirm that they are within the recommended parameters.

Controlling the Excavator’s Movements

Utilise the control levers to manipulate the hydraulic arm and bucket responsively. It is imperative to understand the sensitivity and range of movement of the controls for achieving precision in operations.

Digging and Excavation

Position the excavator close to the intended digging area, ensuring stability on level ground. Utilize the controls to lower the bucket, applying gradual pressure to effectively break the soil or rocks. Control the arm’s movements meticulously to achieve the desired depth and shape while maintaining machine balance to prevent tipping.

Lifting and Moving

When lifting materials, position the bucket or appropriate attachment directly over the load to ensure proper balance and weight distribution. Employ the controls to lift the load smoothly, keeping it near the ground to maintain stability. Any movement while carrying the load should be deliberate and steady, with excessive swinging avoided to uphold safety.

Dumping and Loading

For dumping, position the bucket over the designated area and carefully release the material. When loading materials onto trucks or stockpiles, confirm the excavator’s stability. It is vital to avoid overloading the bucket or attachment beyond its specified capacity to prevent mechanical failure and maintain safety.

Identifying Common Excavator Hazards and Accidents

Despite their utility, excavators can pose significant hazards on construction sites. Common accidents include machine rollovers, contact with overhead power lines, and collisions with other machinery or pedestrians. These incidents often result from operator error, inadequate training, or poor site conditions.

Understanding these risks is crucial for preventing accidents. For instance, machine rollovers can occur due to uneven terrain or overloading the bucket. Contact with power lines can happen if the operator is unaware of their proximity. By identifying these potential hazards, site personnel can take proactive measures to mitigate risks.

Essential Excavator Safety Tips for Operators

Operators hold the key to excavator safety. Conducting pre-operation checks is vital to ensure the equipment is in good working condition. This includes inspecting hydraulic systems, brakes, lights, and the overall structural integrity of the machine. Regular maintenance checks prevent mechanical failures and enhance safety.

Personal protective equipment (PPE) is non-negotiable. Operators should wear hard hats, safety goggles, gloves, and high-visibility clothing to protect themselves from potential injuries. Additionally, clear communication with ground personnel is essential to coordinate movements and avoid accidents.

Operational best practices involve maintaining a safe distance from edges and avoiding overloading the excavator. Operators should also be aware of their surroundings and adhere to speed limits to ensure safe maneuvering on the site.

SAFETY TIPS FOR EXCAVATOR OPERATION

Operating an Mini excavator necessitates strict adherence to safety guidelines. By implementing essential excavator safety tips, operators can maximise productivity while ensuring a secure working environment for themselves and others on the job site. Here are several crucial safety tips to consider:

Operator Training

Ensure that operators receive comprehensive training on excavator operation, which includes safety procedures, control familiarity, and maintenance practices. Ongoing training and certification programmes enhance skills and knowledge, thereby promoting safe and efficient operations.

Personal Protective Equipment (PPE)

Always wear the appropriate personal protective gear, such as hard hats, safety goggles, and high-visibility clothing. Effective PPE protects against potential hazards and significantly minimises the risk of injuries.

Safe Access

Utilise the provided steps, handrails, and handholds when entering or exiting the excavator’s cabin. Jumping or climbing on or off the machine should be strictly avoided, as it can lead to slips, trips, and falls.

Secure Work Area

Before operating the excavator, ensure the work area is clear of personnel, obstacles, and underground utilities. Mark and identify buried pipes, cables, or infrastructure to prevent accidents and potential damage.

Stability and Slopes

Thoroughly assess ground conditions before operating the excavator, particularly in areas with soft or unstable soil. Avoid operating on slopes exceeding the machine’s recommended limits to mitigate the risk of tipping accidents.

Bucket and Attachment Safety

Utilise the excavator’s bucket and attachments within their specified capacity limits. Overloading poses a serious risk to stability and can lead to accidents. Ensure that all attachments are properly installed and that pins and fasteners are securely fastened before operation.

Safe Distance

Maintain a safe distance from bystanders and other workers during excavator operations. Exercise caution when swinging the boom or moving the machine, as the swinging radius can pose hazards to those in proximity.

Refueling, Maintenance, and Inspection

Adhere to proper procedures for refueling the excavator by turning off the engine and avoiding smoking or open flames in the vicinity. Comply with maintenance schedules and conduct routine inspections to ensure smooth excavator operations.

Insurance for Mini Excavator

It is strongly advised to obtain insurance coverage for an excavator. This coverage will mitigate financial losses resulting from accidents, damages to the excavator, third-party injuries or property damage, theft, vandalism, and other unforeseen circumstances. Insurance ensures the equipment is financially protected against potential liabilities and costs that may arise during its use.

The Importance of Safety in Mini Excavator Operation

Safety is paramount in excavator operation, given the inherent risks associated with heavy machinery. The implementation of rigorous safety protocols not only protects operators and personnel on-site but also safeguards the machinery itself, preventing costly damages and downtime. A strong safety culture fosters accountability and awareness, reducing the likelihood of accidents resulting from human error or negligence. By prioritising safety through comprehensive training, proper use of personal protective equipment, and adherence to operational best practices, organisations can create a secure work environment that enhances overall efficiency and productivity. Ultimately, committing to safety is not merely a regulatory requirement; it is an essential cornerstone of effective excavator operation and responsible construction practices.

Safety Guidelines for Personnel Around Excavators

Safety extends beyond the operator to include workers in the vicinity of excavator operations. Personnel should maintain a safe distance from the machine and stay within designated walkways. Barricades and warning signs are effective in keeping unauthorized personnel out of danger zones.

Understanding the machine’s swing radius and blind spots helps personnel stay alert and avoid accidents. Workers should also communicate with operators using hand signals or radios to ensure everyone is aware of the excavator’s movements.

Site supervisors should conduct regular safety briefings and drills to familiarize personnel with emergency procedures and evacuation routes. This proactive approach fosters a culture of safety and preparedness.

The Critical Role of Site Supervisors and Safety Officers

Site supervisors and safety officers play a pivotal role in ensuring excavator safety. Their responsibilities include conducting risk assessments, implementing safety protocols, and monitoring compliance with regulations. Regular inspections and audits help identify potential hazards and rectify them promptly.

Supervisors should ensure that all operators are adequately trained and certified to handle Mini excavators. They must also facilitate ongoing safety training sessions to keep everyone updated on the latest best practices and safety standards.

By fostering open communication and encouraging feedback, supervisors can create a safe and supportive work environment where safety is prioritized.

Real-life Case Studies and Impact of Improved Safety

Real-life examples underscore the importance of excavator safety. One case study involves a construction site that implemented comprehensive safety training and reduced accidents by 30% within a year. This success was attributed to regular safety audits, improved communication, and strict adherence to safety protocols.

Another example highlights the consequences of neglecting safety. A site experienced a fatal accident due to inadequate training and failure to conduct pre-operation checks. Such incidents serve as reminders of the critical need for vigilance and adherence to safety measures.

Statistics show that investing in safety not only protects lives but also enhances productivity and reduces downtime. By learning from these examples, construction sites can implement effective safety strategies and create a safer work environment.

The Shared Responsibility for Safe Mini Excavator Operations

The responsibility for excavator safety is a shared one, involving operators, site personnel, supervisors, and safety officers. Each stakeholder plays a vital role in maintaining a safe working environment. By working together, they can identify hazards, implement safety measures, and prevent accidents.

A proactive approach to safety involves regular training, open communication, and a commitment to continuous improvement. By prioritizing safety, construction sites can protect their workers, improve productivity, and foster a positive safety culture.

Engage with Our Community for More Safety Insights

We value your input and encourage you to share your thoughts and experiences with excavator safety. Whether you have additional tips, questions, or stories to share, we welcome your feedback. Join our construction community to stay updated on the latest safety developments and best practices.

Let’s work together to create safer construction environments and ensure that everyone returns home safely at the end of the day. Feel free to share this post with colleagues and fellow construction enthusiasts who may benefit from these insights.

Encouraging Community Engagement on Safety

Fostering a culture of safety within the construction industry requires the active involvement of all stakeholders. We invite you to engage with our community and share your insights, experiences, and best practices related to excavator operation and safety. Your contributions can play a crucial role in enhancing awareness and promoting effective safety strategies.

Participate in discussions, contribute to forums, and attend workshops focused on safety innovations and regulations. By sharing your expertise, you not only help educate your peers but also strengthen the collective commitment to creating safer working environments. Remember, safety is an ongoing conversation, and your voice matters. Let’s collaborate to ensure that high standards of safety are upheld, allowing everyone to return home safely after each workday. Join us in building a robust network of safety-conscious professionals dedicated to making a difference in the industry.

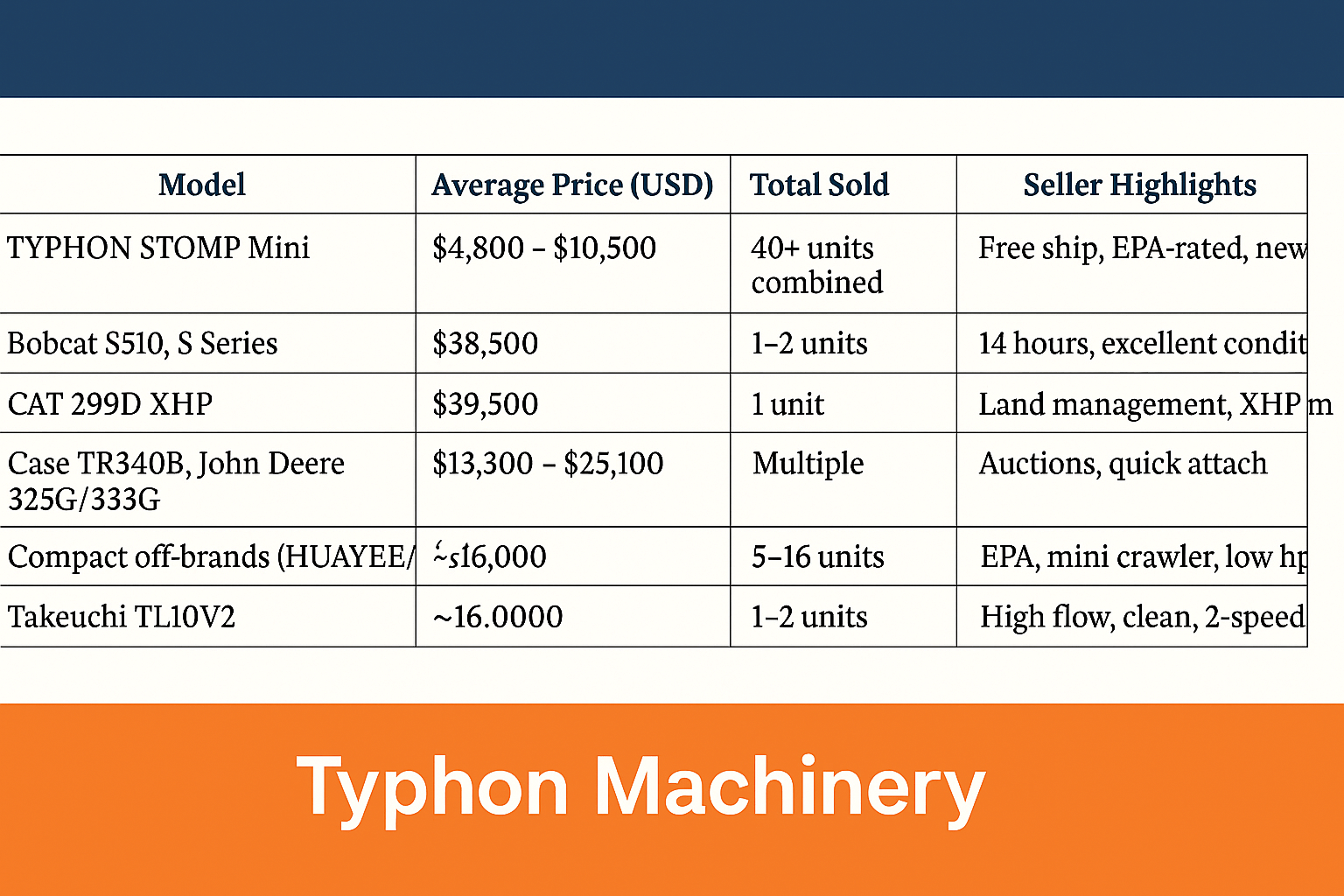

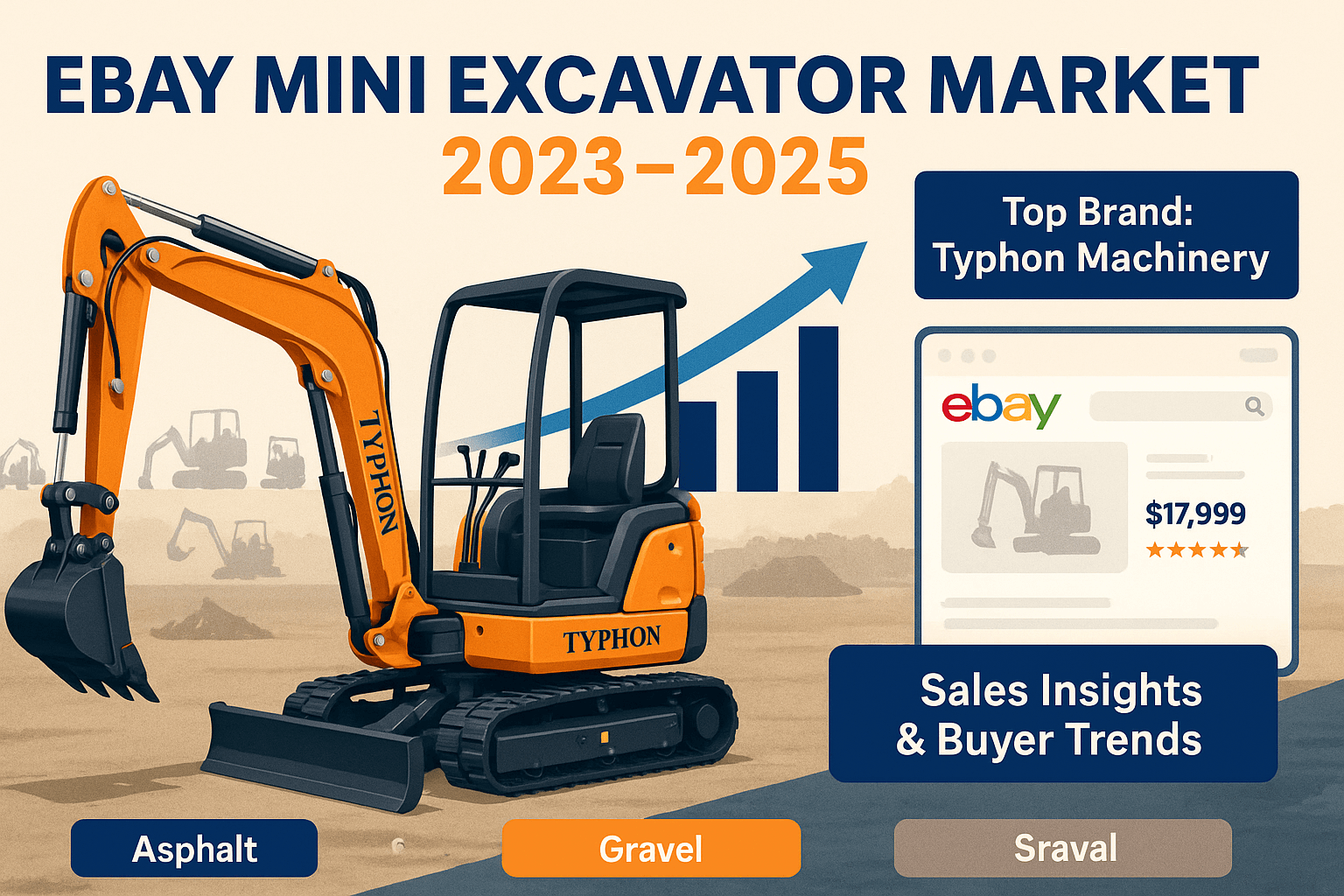

Call to Action for TYPHON Machinery Mini Excavators

Investing in TYPHON Machinery mini excavators means prioritizing safety and efficiency in your construction operations. Our mini excavators are designed with cutting-edge technology that enhances operator safety while maximizing productivity on site. We invite you to explore our range of models, each equipped with features that ensure compliant and safe operation, including superior visibility and intuitive controls.

Don’t compromise on safety or performance—contact us today to learn more about how TYPHON Machinery can elevate your excavation projects. Request a demo, consult with our knowledgeable sales team, or visit our website to access resources that will help you make an informed decision. Let’s work together to build a safer, more efficient future in construction.